What is grading of aggregates??

- Grading of aggregates is procedure to find out the particle size distribution of various aggregates.

- This method helps to determine the aggregates size and percentage used in construction works.

- Coarse aggregates are graded as, 80mm, 63mm, 40mm, 20mm, 10mm

- Fine aggregates are graded as. 10mm, 4.75mm, 2.36mm, 1.18mm. 600micron, 300micron, 150 micron

- Basically, grading of aggregate is to find out size of specific aggregates and its retention on specific sieve size.

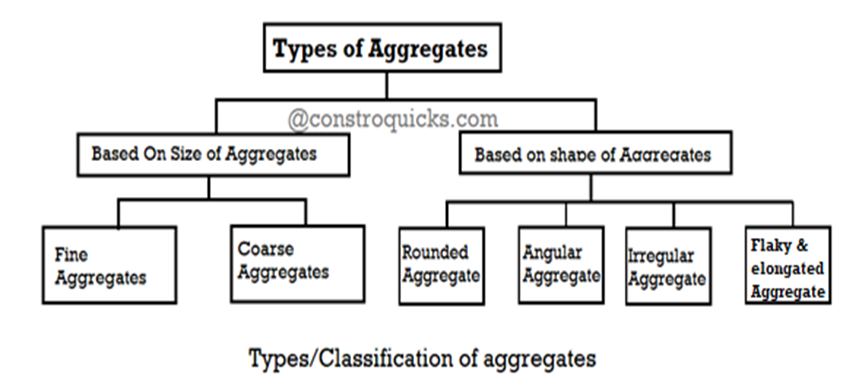

Classification of aggregates based on grading:

- Uniformly Graded Aggregates

- Well graded Aggregates

- Gap Graded Aggregates

- Open graded

- Poorly graded

Check the classification of aggregates>>>

- Uniformly Graded Aggregates:

- In this type of aggregates, aggregates has more prominent percentage of particular size of aggregates.

- Eg. Aggregates which has 16mm size of aggregates 80%, and remaining 20% is combination of rest sizes.

- In uniformly graded aggregates, there will be high chances to form a void, and to fill up this void cement paste requirement is very high. Due to this concrete can be more porous.

- And the changes of high permeability and low stability is there

- Well graded Aggregates

- This consists almost all sizes of particles and due to this voids in concrete is almost filled by small size aggregates and this form a compacted mass.

- Due to less voids formations, this is less permeable and has high stability.

- This is the most used and preferred aggregates, as it suitable for every type of construction.

- Gap Graded Aggregates:

- In this type of aggregates, a certain size of aggregate in missing (almost has zero percentage).

- This has moderate voids, and moderate permeability and low stability.

- This are generally used for the construction, where economical mix is required.

- This is also used when to improve aesthetic purpose.

- Open graded:

- In this type, the smaller size aggregates are present.

- Due to this, air voids are more and permeability is also more.

- Poorly graded

- In this type, the particular size of aggregate in much and other are very less.

- Due to this, the void formation is more, stability is less and permeability is more.

Grading of aggregates

- The grading of aggregates is mainly depend on particle size of aggregates.

- To find out the particle size distribution, sieve analysis is performed.

- Grading is very important factor , which influences the strength and durability of concrete. Also this is important factor for mix design of concrete.

- Before selection on sand/aggregates for construction, their sieve analysis has to be made, to find out the gradiation of aggregates, and depend on result decision has to be made.

Grading Limits of aggregates:

Following are the grading limits of aggregates,

Grading Limit for Coarse Aggregates: (Based on Clause 4.1 and 4.2 of IS: 383- 1970)

| IS Sieve | Percentage passing for single sized aggregates of nominal size(mm) | |||||

| 63 mm | 40 mm | 20 mm | 16 mm | 12.5 mm | 10 mm | |

| 80 mm | 100 | – | – | – | – | – |

| 63 mm | 85 – 100 | 100 | – | – | – | – |

| 40 mm | 0 – 30 | 85 – 100 | 100 | – | – | – |

| 20 mm | 0 – 5 | 0 – 20 | 85 – 100 | 100 | – | – |

| 16 mm | – | – | – | 85 – 100 | 100 | – |

| 12.5 mm | – | – | – | – | 85 – 100 | 100 |

| 10 mm | 0 – 5 | 0 – 5 | 0 – 20 | 0 – 30 | 0 – 45 | 85 – 100 |

| 4.75 mm | – | – | 0 – 5 | 0 – 5 | 0 – 10 | 0 – 20 |

| 2.36 mm | – | – | – | – | – | 0 – 5 |

Grading Limits for Fine Aggregates: (Based on Clause 4.3 of IS: 383 – 1970)

| IS Sieve Designation | Percentage Passing | |||

| Grading Zone I | Grading Zone II | Grading Zone III | Grading Zone IV | |

| 10 mm | 100 | 100 | 100 | 100 |

| 4.75 mm | 90 – 100 | 90 – 100 | 90 – 100 | 95 – 100 |

| 2.36 mm | 60 – 95 | 75 – 100 | 85 – 100 | 95 – 100 |

| 1.18 mm | 30 – 70 | 55 – 90 | 75 – 100 | 90 – 100 |

| 600 microns | 15 – 34 | 35 – 59 | 60 – 79 | 80 – 100 |

| 300 microns | 5 – 20 | 8 – 30 | 12 – 40 | 15 – 50 |

| 150 microns | 0 – 10 | 0 – 10 | 0 – 10 | 0 – 15 |