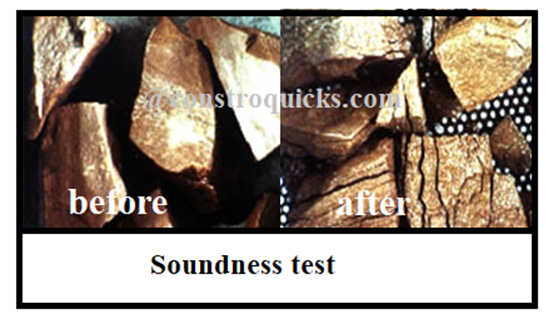

Soundness Test of Aggregate

The soundness test of aggregates is conducted to determine their resistance to weathering actions, such as temperature variations, rain, freeze-thaw cycles, and so on. Consequently, this assessment helps ensure the quality and longevity of the materials used in construction.

The porous and less dense aggregates are more prone to freezing and thawing actions; consequently, their disintegration occurs quickly and prematurely. Therefore, using such aggregates in construction can lead to significant issues over time.

Using such aggregates in road construction not only degrades the quality of the road, but furthermore, it can also lead to accidents and result in poor-quality workmanship.

Objective:

To assess the ability of aggregates to withstand weathering effects, and furthermore, to evaluate their overall durability, it is essential to conduct rigorous testing and analysis.

IS Code:

IS: 2386 part-V.

Apparatus:

- Balance: Specifically, it includes 500 gm (with a least count of 0.1 gm) and 5000 gm (with a least count of 1 gm).

- 500gm (0.1gm least count)

- 5000gm (1gm least count)

- Oven

- Sieve sizes include: 80 mm, 63 mm, 40 mm, 31.5 mm, 25 mm, 20 mm, 16 mm, 12.5 mm, 10 mm, and additionally, 8.0 mm, as well as smaller sizes such as 4.75 mm, 4.0 mm, 2.36 mm, 1.18 mm; furthermore, it also includes finer sieves like those measuring 600 micron, 300 micron, and finally, 150 micron.

- Wire mesh basket

- Container

Chemicals:

- Sodium Sulphate Solution: This solution is essential for conducting the soundness test, as it helps in evaluating the resistance of aggregates to weathering effects.

- Magnesium Sulphate Solution

Preparation of sample:

- Select any two sieve sizes and sift the sample through them.

- Take 100 grams of the retained material for further testing.

- For example, for fine aggregates:

| Passing on | Retained on | Sample weight |

| 10 mm | 4.75 mm | 100gm |

| 4.75 mm | 2.36 mm | 100gm |

| 2.36 mm | 1.18 mm | 100gm |

| 1.18 mm | 600 micron | 100gm |

| 600 micron | 300 micron | 100gm |

For Coarse aggregates:

| Size | Sample weight |

| 10 mm to 4.75 mm | 1000gm |

| 20 mm to 10 mm | 1000gm |

| 40 mm to 20 mm | 1000gm |

| 63 mm to 40 mm | 1000gm |

| 80 mm and larger | 1000gm |

Procedure:

- Take the weight of sample as W1 gm.

- Immerse the sample in a solution of either sodium sulfate or magnesium sulfate for at least 16 to 18 hours.

- After that remove sample from solution and drain the solution completely and allow it to drain for 15 minutes.

- Dry the sample in an oven at a temperature of 105 to 110 degrees Celsius.

- Repeat this immerging and drying process 5 times for individual sample.

- After 5th cycle note down the dry weight of sample as W2 gm.

Result:

Percentage loss = (W1-W2) x 100/W2

REPORT

The should be reported in following manners,

- Type of solution used:

- Range of sieve size selected:

- Weight of sample before the test (W1) gm: Initially, this weight is crucial for determining the percentage loss after conducting the soundness test.

- Weight of sample after test (W2) gm

- Percentage loss: