- Cement mortar is mixed and homogeneous paste of cement, sand and water.

- As name suggest, the main binding material in cement mortar is cement.

- Depending upon the usability, working condition and purpose, the proportion of cement sand can be decided.

- Cement mortar also provides high resistivity and strength against water.

- Admixture can be added to cement mortar for particular or special purposes and special types of mortars can be made.

- This is the most common and typical type of mortar which is strong and widely used in construction.

- This can also be used for heavily loaded structures. And can be used in plastering, masonary, joineries, pointing and other maintenance purposes.

- The ratio of cement to sand in cement mortar can be vary from 1:2 to 1:6.

Proportion of Cement Mortar

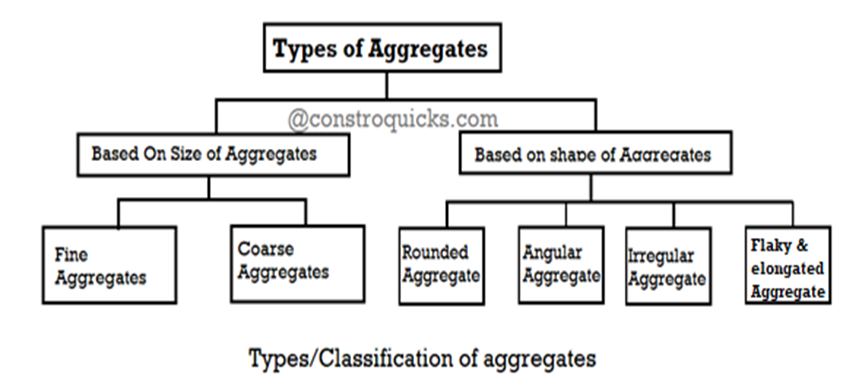

The proportion of cement mortar is depending on different components like

- Use of mortar

- Working conditions

- Workability

- Strength required

- Weather conditions

The good cement mortar can be achieved by adding correct and simple ratio of raw materials like cement, sand and water.

As per IS: 2260-1981 (Indian Standard), the strength of the mortar depends upon the proportion of cement and sand. Strength obtained with the various proportions of cement and sand are as follows. Following are some random cement mortar proportions which is commonly used in construction,

| Masonary works | |

| Ordinary masonry work with brick/ stone as a structural unit | 1:3 to 1:6 |

| Reinforced brick work | 1:2 to 1:3 |

| all work in moist situations | 1:3 |

| Architectural work | 1:6 |

| Load Bearing structures | 1:3 to 1:4 |

| Plaster work | |

| External Plaster and Ceiling Plaster | 1:4 |

| Internal Plaster | 1:5 to 1:6 |

| Flooring works | 1:4 to 1:8 |

| Pointing work | 1:1 to 1:3 |

Properties of Cement Mortar

- Impervious surface: good cement mortar (well proportioned, maintained and laid) provides impervious surface.

- Good binding Property: When water is added to dry mix of sand and cement, hydration process starts and it start forming a CSH gel and binding of cement with surrounding sand particles starts forming. This also provides strength to the cement mortar.

- Shrinkage: A cement mortar having proportion more than 1:3 is prone shrinkage and to reduce the loss of shrinkage precautionary action and care should be taken.

- Porosity in plastering: In case of plastering the surface will remains porous

Uses of Cement Mortars:

- It provides high strength to structures and it can be used inn structure which are subjected to wet and damp conditions like piers, foundations, dams etc.

- Cement mortar is mainly used in masonary to blind masonary units like bricks, stones, blocks.

- It can be used as Damp proof course in construction and it is resist the water.

- It can be used for internal as well as external plastering and to make surface impervious.

- It also can be used in exposed works such as exterior walls, parapet walls and engineering construction with bricks of high strength.

- Cement mortar also can be used with concrete to form a binding layer between RCC and PCC.

- Cement mortar is filler materials and can be used in ferro cement works and other types of masonary.

- Cement mortar also can use to fill cracks, joints in new construction and old construction.

- Use of cement mortar provides neat and clean finished surface to structure and concrete work.

Precautions:

- It should be completely used with 30 minutes after mixing of water into cement and sand as cement as limited setting time.

- If it used in masonary, masonary units should be well soaked in water before laying. As there is a chances of loss of water from mortar to masonary units if it is dry.

Before applying plastering, wall should be kept wet at least seven days.

This really is an incredibly amazing powerful resource that you’re offering and you just provide it away cost-free!! I comparable to discovering websites that view the particular price of providing you beautiful learning resource for zero cost. We truly dearly loved examining this web site. Be thankful!

Thank you so much