Selection of aggregates should be done on basis of their properties. The good quality aggregates should be selected for the construction.

How to select the aggregates for construction?

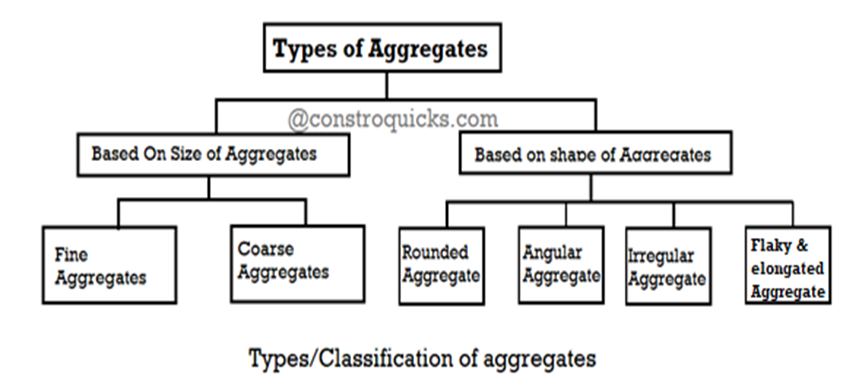

Size & Shape

- Angular and irregular aggregates should be selected, as they provides good bond strength and mechanical strength.

- Flaky, elongated and rounded aggregates is not referred as good quality aggregates but can be used in less valued/important work like compound RCC wall, zero load carrying elements.

Surface Texture:

- Roughness and porosity of aggregates offers lesser workability but good bond strength and mechanical strength. Pores in aggregates are filled with cement in concrete which offers bonding and enhances the strength of concrete.

- Rounded and smooth aggregates should be avoided.

Specific Gravity

- Lesser specific gravity indicates the low strength (weaker aggregates) and more porosity. Higher specific gravity indicates more strength of aggregates and less porosity (which increases the durability of concrete.)

- Higher specific gravity aggregates should be used. The average value of specific gravity is 2.68. and aggregates whose specific gravity is more than 2.68 is considered as good quality aggregates.

Fineness Modulus:

- More fineness of aggregates means the aggregates is coarse. Lesser fineness aggregates mean aggregates is finer. Depending upon the particular activity aggregates should be selected.

- For example, for plastering: lesser fineness required.

- Bulking of sand should not be avoided.

Voids:

- The voids should be minimum and not more that the average permissible values. And considered as good quality aggregates.

- Voids in aggregates makes concrete weaker, porous.

| Average Void Percentage | |

| River sand | |

| Fine | 43 |

| Coarse | 35 |

| Mixed and moist | 38 |

| Mixed and dry | 30 |

| Broken stone, graded | |

| 25 mm maximum size | 46 |

| 50 mm maximum size | 45 |

| 63 mm maximum size | 41 |

| Stone screenings | 48 |

Deleterious materials:

- Aggregates should be free from impurities like mica, shell, coal, bones, clay etc. Impurities reacts with alkalis in cement and leads to cracking, expansion and deterioration of concrete. There are many tests to detect the impurities in concrete. This leads to weaken the bond strength.

Impact value

- Impact values the factor to measure the resistant of aggregates against shocks and impact. A higher impact value indicates the toughness of aggregates.

- The impact value should not be more than, (As per IS 383:1970, Specification for coarse and fine aggregates)

- 30 for Wearing surfaces

- 45 For other than wearing surfaces

Crushing Value

- Crushing values, the factor to measure the resistant of aggregates against hardness. The crushing value gives the resistance of a coarse aggregate to crushing under the application of compressive load.

- The Limiting value for crushing should not be more than, (As per IS 383:1970, Specification for coarse and fine aggregates)

- 30 for Wearing surfaces

- 45 For other than wearing surfaces

Abrasion Value

- Abrasion values the factor to measure the resistant of aggregates against abrasion. High abrasion means aggregates are hard enough to resist abrasion. This tends to decrease the chance of wear and tear in concrete.

- The Limiting value for crushing should not be more than, (As per IS 383:1970, Specification for coarse and fine aggregates)

- 30 for Wearing surfaces

- 50 For other than wearing surfaces