Table of Contents

Wood as a Structural Material – Timber Beams

Structural Properties of Wood

1. Directional Properties:

- Strength parallel to the grain in compression is 5 to 10 times that at right angles.

- This ratio is higher in tension.

- The modulus of elasticity parallel to the grain is 100 times that at right angles to the grain.

2. Bending:

- Timber is 1/12th the density of steel and has about 1/10th the strength of steel. Hence by weight it is stronger of the two. Bending strength is lower in deep beams than shallow beams.

3. Modulus of Elasticity:

- The Modulus of Elasticity is not affected by Drying

4. Axial Tension:

Timber is strong in Tension parallel to the grains.

- Storage of Cement: Quality, Steps???

- Field test for cement

- Differences between OPC and PPC Cement: Which is Best?

- Properties of good cement

- Uses of Cement

5. Shear:

The Shearing Stress increases at base of Shakes, Checks, and where there is sudden change of

cross-section.

As Shear stresses in Beams are not much in the central portion, notches in the central

portion will not have much effect on the design of Shear but will affect Bending Stresses.

6. Working Stresses:

These are as per the following Table

7. Timber Beams:

A. Bending in Timber

is based on the Flexural Formula and based on the following.

1. Plane Section Remains Plain After Bending

2. The Stresses are within Elastic Limit

3. Young’s Modulus is same for Tension and Compression

Tests have shown that Timber does behave like a homogenous material and has almost equal capabilities in

compression and tension.

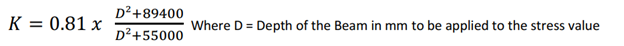

B. Form Factor:

- In a deep Beam the stress decrease from the outer most fiber towards the neutral axis is less

than in a shallow beam. The carrying capacity of a Deep Rectangular Beam is less. The Form Factor K is

applied for rectangular Beams greater in depth than 300mm. - Different Types of Wooden Sections may have different Form Factors which are also based on the shape of the

section and may have values lesser than 1 or greater than 1. E.g. for square sections where the load is in the

direction of the girder the form factor shall be taken as 1.414

C. Effective Span:

Least of the Following for Simple Supported Beams

1. Centre to Centre between supports or

2. Clear span + Half of Required Bearing at each end

And Centre to Centre between Supports for Continuous Beams

Effective Span to be considered from Face of Support to Free End for Cantilever

D. Width:

The minimum width of a beam shall be greater of the following

1. 50mm

2. 1/50 of the Span