Table of Contents

Aggregate Impact value:

- Aggregate impact value is defined as the ability of aggregates to have resistance against shock and impact, toughness.

- It Also can be defined as the load at which aggregates start cracking due to the impact and shocking.

- In Impact test of aggregate, the aggregates are tested to find out toughness of aggregate to absorb shock and impact.

- Impact and shock can break the aggregates and it can leads to pavement failure.

- Also read: Properties of aggregates>>>

- Also read: Types of aggregates>>>

- Also read: How to select the aggregates for construction>>>

- Also read: Grading of aggregates>>>

Impact Test:

(As per IS: 2386(Part IV)-1963 Methods of test for aggregate for concrete)

Objective:

To Determine the impact value of coarse aggregates.

IS Standards:

IS: 2386(Part IV)-1963 Methods of test for aggregate for concrete

Apparatus & Equipment:

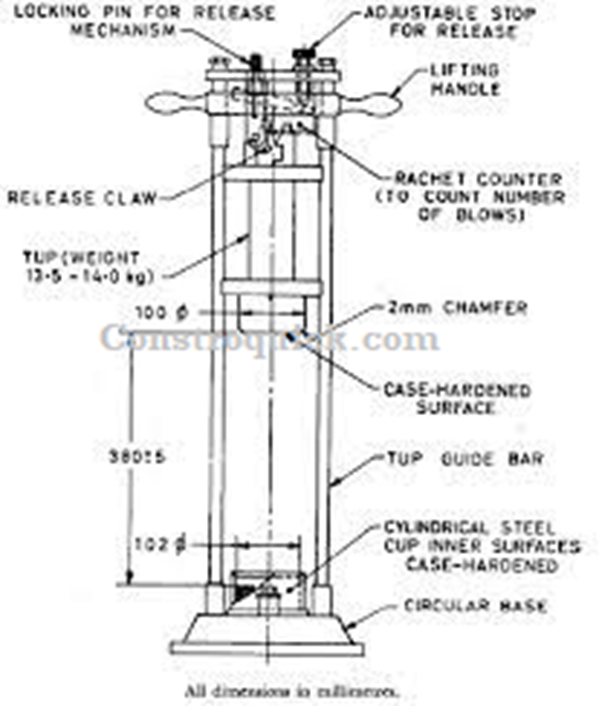

- Impact Testing machine

- Sieves of size 12.5mm & 10mm.

- Cylindrical metal measure

- Tamping Rod

- Balance (0-10kg)

- Oven(3000c)

Sample Preparation of aggregates:

- Aggregate sample should be passed through the 12.5mm IS sieve and retain on the 10mm IS sieve.

- The aggregate sample should retained on 1.mm sieve. And oven dried for at least 4 hours in oven at temperature 0f 110º C.

- The cylindrical steel cylinder is filled with sample filled about 1/3 full and tamped with rod with 25 strokes. Further fill the cylinder again with 1/3 quantity of sample and tamped with rod with 25 strokes. Repeat the same procedure one more time.

Procedure:

- The cylindrical cup should be filled with 3 equal layers of aggregates and each layer tamped with 25 strokes by rounded tamping rod. Surplus the aggregate struck off, using the straight edge of tamping rod.

- The net weight of aggregate in cylinder is measured by weighing machine and considered it as Wa.

- The cylindrical cup is fixed at base of impact testing machine and the test sample is also placed.

- The testing machine also has the hammer. The hammer is raised until its loser face is 280mm above the upper surface of the aggregate cup. And allowed freely to fall on cup with impact 15 times.

- After this, remove all sample from cup.

- Sieve all the sample on 2.36mm IS sieve until no significant amount passes through sieve.

- Measure all the materials retained through on 2.36mm IS sieve upto accuracy of 0.1g (Wb)

Data Recording and Calculation:

| Observations | Sample 1 | Sample 2 |

| Total weight of dry sample (W1 gm) | ||

| Weight of portion passing 2.36 mm sieve (W2 gm) | ||

| Aggregate Impact Value (percent) = W2 / W1 X 100 |

- Mean =

Calculation:

The ratio of the weight of portion retained on 2.36mm sieve formed to the total weight of dry sample in each test is to be expressed as a percentage, to the first decimal place.

Aggregate impact Value = (WB / WA) × 100

For example,

Total weight of dry sample (Wa) = 300gm

Weight of portion passing 2.36 mm sieve (WB gm)= 80gm

Aggregate Impact Value (percent) = WB / WA X 100 = 80 gm / 300 gm = 26.67 (Impact Value)

Where,

W1= Weight of the fraction passing through 2.36 mm IS sieve.(220 gm)

W2= Weight of sample retained on 2.36 mm IS sieves. (80 gm)

W1+W2 = Total Weight of Sample (220 + 80 = 300 gm)

Result:

The Aggregate Impact Value is 26.67%

Precautions:

- Check the machine before testing.

- Wear Safety shoes and goggles while performing the testing.

- Use the hand gloves while removing the aggregates sample from oven.

- Take care of sieve before and after testing. Dust the sieve properly before and after using them.

- All equipment and apparatus should be clean before and after each use.

Recommended Aggregate Impact Test Values

| Aggregate Impact value | Nature |

| <20% | Exceptionally strong |

| 10-20% | Strong |

| 20-30% | Satisfy for surface course |

| >35% | Weak for surface course |

Maximum Allowable Impact Value of Aggregate for Different Types of Pavements

| Sr. No. | Types of Pavements | Aggregate Impact Values (Max.) |

| 1 | Water Bound Macadam (WBM) Sub- Base Course | 50 |

| 2 | Cement Concrete, Base Course | 45 |

| 3 | i) WBM base course with bitumen surfacing | 40 |

| ii) Built up- Spray grout, base course | ||

| 4 | Bituminous macadam, base course | 35 |

| 5 | i) WBM, surface Course ii) Buit-up spray grout, surface course iii) Bituminous penetration macadam iv) Bituminous macadam, binder Course v) Bitumen surface dressing vi) Bitumen carpet vii) Bituminous / Asphaltic concrete | 30 |